CyberFab

Production

- production jobs can be nested and scheduled automatically based on pre-set requirements and instantaneous status of production machines

- progress of production jobs is continuously monitored, enabling to trace individual parts throughout the process and update the stock on the fly

- within a production cell, workstations downstream of the cutting machines can be integrated as well, including logistics between them, having the complete process up to the final product scheduled and monitored

Motion control is taken to the next level by introducing proprietary interpolation algorithms, optimized for high machine dynamics and fine contour quality. CyberFab Control thus ensures the best cutting results for the most demanding laser applications while maintaining a high level of flexibility that characterizes all MicroStep systems

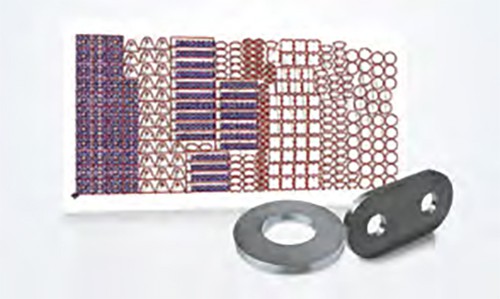

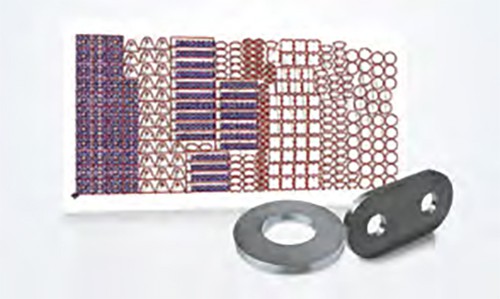

- Control of plasma, laser, oxyfuel and waterjet cutting; plasma, laser, inkjet and micro-percussion marking; milling and drilling

- Processing of sheets, pipes, profiles, beams, domes and other custom shapes

- Automatic switching of technologies & multitasking

- 3D objects scanning and automatic motion adaptation to true shape of material

- Automated bevel cutting with all technologies

- Auto-Calibration of Tool Geometry – ACTG® (patented by MicroStep)

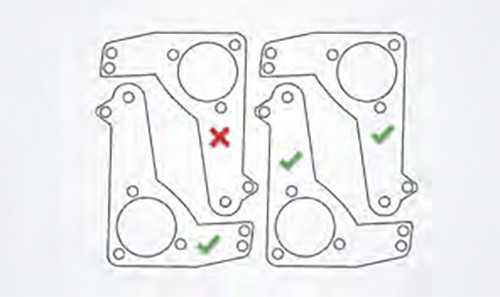

- Advanced Bevel Corrections – ABC

- Additional Beveling Process – ABP® (patented by MicroStep)

- Self-Teaching Height Control – STHC

- Smart Z Movement – SZM

- Integration of material handling systems

- Support for fully automatic operation of machinery

- Technological parameters shared between production machines – instant production setup

- Configuration and production databases of machines shared with CyberFab applications – highly accurate evaluation of planned production

- Targeted system communication with users according to user competences – receive only messages that are relevant to your job

- Intelligent operator interface displays only the functional elements that are related to currently running processes – highly focused operation

- Intranet applications with access to production, utilization, operation and maintenance info for each machine through company intranet – machine apps available conveniently and remotely

Each machine with CyberFab Control includes a transparent web interface with machine overview and easy access to its intranet applications. The following apps are available via intranet: Machine Manager, Service Manager, User Manager, Machine Stats, Dashboards and Manuals. Apart from apps, the web interface also notifies of actual service alerts.

CyberFab® Manager provides production management for MicroStep based manufacturing systems. In combination with the CAM software Asper® or mCAM it allows to automatically nest complex cutting orders and projects on assigned stock material and distribute the cutting tasks to assigned cutting machines for processing. After completion, it automatically updates order progress and stock statuses.

The suite also provides tools to control the complete process of manufacturing parts and assemblies in a single integrated system, by managing next operations such as bending, deburring, welding or others that are required within the same project. It helps to reduce the need for operator input, reduce work-in-progress and save material.

The module Workstation Manager provides tools to control the complete process of manufacturing parts and assemblies:

- operators on workstations downstream of the cutting process (a press brake, a saw, a deburring machine…) receive task lists with processing instructions and information on parts flow

- tasks are either displayed on a screen, or can be directly interfaced to other smart equipment

- completed operations are logged to ensure the production database is up-to-date at all times

CyberFab® Manager greatly automates the processing of cutting orders. Even complex orders or projects can be executed automatically based on priority, material type and thickness. The process will flexibly adjust according to availability of material – CyberFab® Manager can be directly interfaced to existing stock management system. If there is not enough material available for a particular order, the system will notify the responsible person to order the required amount.

For cutting machines equipped with MicroStep´s control system and CAM software Asper® or mCAM, individual parts of a cutting order are automatically nested on their assigned material blanks. Depending on priority and availability of material, orders with more pressing deadlines are processed first. The generated cutting plans are distributed automatically – the operator on a cutting machine will see only the orders that are assigned to the particular machine.

CyberFab® Manager greatly automates the processing of cutting orders. Even complex orders or projects can be executed automatically based on priority, material type and thickness. The process will flexibly adjust according to availability of material – CyberFab® Manager can be directly interfaced to existing stock management system. If there is not enough material available for a particular order, the system will notify the responsible person to order the required amount.