Digital heart of MicroStep production systems.

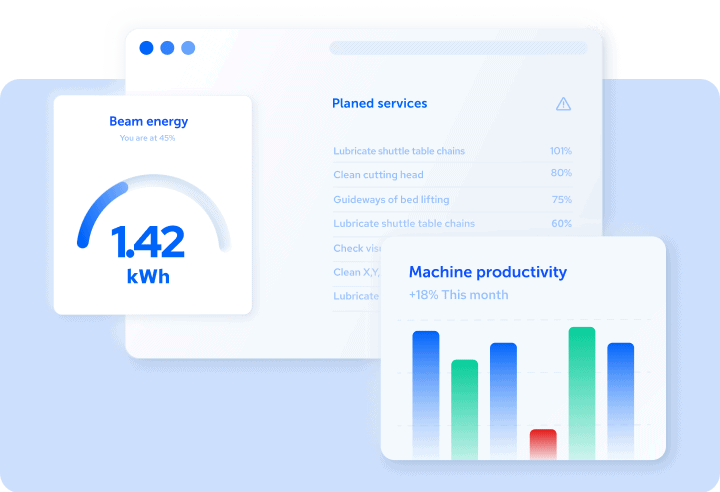

CyberFab is a suite of digital tools and apps that enable efficient operation, planning and management of MicroStep based production systems through automation and digitalization

CyberFab digital ecosystem addresses the requirement for a comprehensive approach to fabrication machinery in terms of production management, performance tracking and connectivity within the frameworks of smart industry and IIoT.

The core of the ecosystem is the new generation MicroStep control system CyberFab Control that works as an edge device for continual collecting, storing and evaluating of data in three main areas of CyberFab – Performance, Production and Diagnostics.

CyberFab suite provides digital tools and apps such as CyberFab Manager, Machine Manager, User Manager, Workstation Manager or Service Manager that streamline operator experience, automate production processes, digitize and manage production machines and enable seamless integration of MicroStep machinery into smart factory solutions.

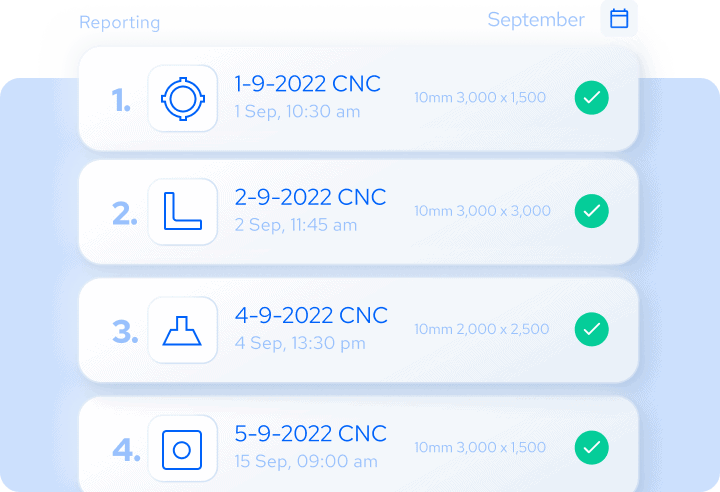

Production managment

data powered production planning & tracking

Traceability

Data collection

continuous data stream & edge processing

Extensibility

open to connecting external devices

Intelligent diagnostics

preventive & predictive maintenance based on big data analysis

Connectivity

integration with north-bound information systems

data analysis

north-bound information systems

CyberFab

Performance

CyberFab

Production

CyberFab

Diagnostics

Case studies

connected production cellThe company Ambros Schmelzer is „mastering metal“: their latest addition targets an advanced level of large-format plate cutting automation.

high-volume manufacturingA pioneering tandem: MicroStep and Demag Cranes

scaled up the production output for mining equipment giant ZMJ

CyberFab – powering and powered by MicroStep

CyberFab groundworks

In 1998, MicroStep launched the first ever Windows based control system in CNC cutting industry – this opened the doors to a functionality inconceivable before. From parameter databases and remote diagnostics through patented digital compensation of technological and mechanical inaccuracies to advanced production planning and automated production management – the emphasis has always been on digital innovation.