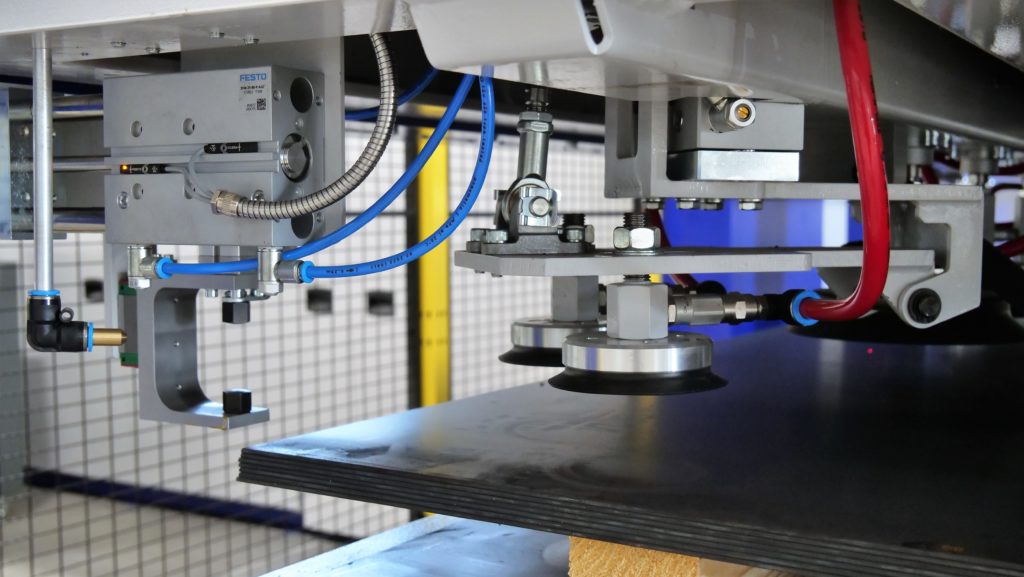

One cutting machine, two autonomous, connected loading and unloading zones and two sorting workplaces: the setup in the factory of Schmelzer’s Czech subsidiary is well thought out, aiming at maximum efficiency and flexibility. A 6 x 2 m MicroStep MSF Pro Carbon machine equipped with a 6 kW beam-shaping fiber laser is well suited for matching the varying production requirements. The system consists of three zones with three shuttle pallets and two loading/unloading positions that are served by MicroStep’s special double loader MSLoad Twin. This allows to run two individual cutting projects or two cutting batch lists at a time – while the first position is intended for batches of standard 3 mm mild steel plates, the second one is for any other cutting tasks and materials.

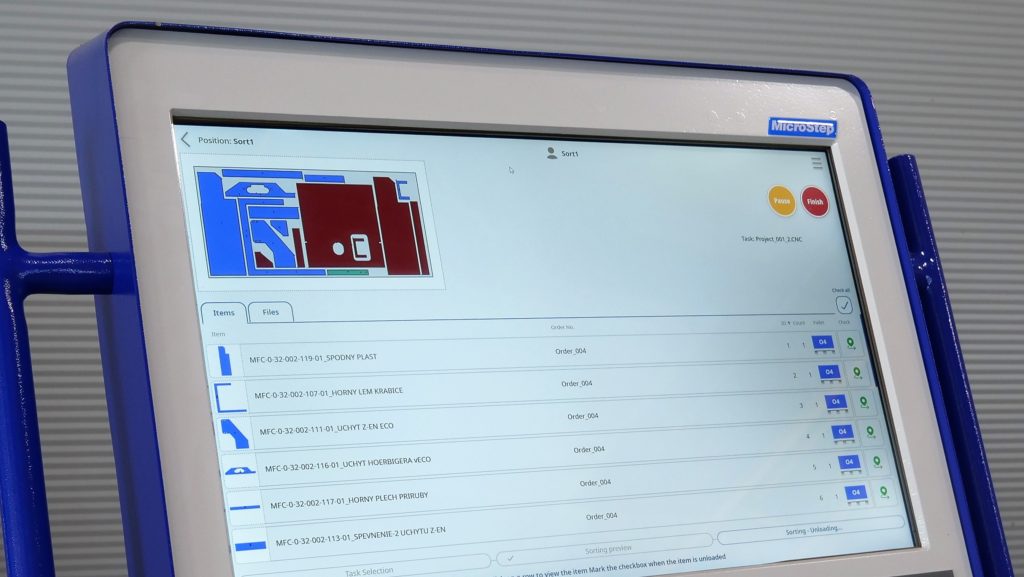

Sorting managed by Workstation Manager

The core here lays in digital automation – the whole production cell is automated with MicroStep’s CyberFab Manager that ensures automatic generation and distribution of cutting programs based on production orders, stock management and production tracking. The operators follow instructions displayed on loader terminals e.g. about materials to be loaded. The system also decides autonomously where to unload cut parts and provides all information to the sorting interfaces. Part of the project are also two independent manual sorting workplaces equipped with visual sorting assistance by Workstation Manager, including all information about orders and executed programs stacked on any pallet. The system provides interface to Schmelzer’s Microsoft Dynamics ERP via TSQL to automate data-flow and production tracking.