MicroStep and Demag Cranes shook their hands in a pioneering tandem: in close cooperation, the companies developed an automated sheet processing line for China’s leading mining equipment manufacturer Zhengzhou Coal Mining Machinery Group. In total, 8 MicroStep plasma cutting machines are loaded with plates by an automatic 9t process crane from Demag. As a result, the company achieved a 40% production increase.

The Chinese mining industry of the last decade has been booming and so did the mining equipment sector. The Zhengzhou Coal Mining Machinery Group is one of the market leaders both for stationary equipment for roof and long-wall supports as well as for mobile machinery that operates in mines. At its plant in Zhengzhou, the capital of Henan province, the company is running a production line for automated plate processing consisting of several double-gantry MicroStep cutting machines and a Demag process crane, which is responsible for storage and retrieval of the plates as well as the feeding of the cutting systems in a 24/7 operation. At the heart of the system is the production management software CyberFab Manager from MicroStep, which controls the entire production process.

The investment has paid off for ZMJ: Every day, the cutting line is able to process up to 155 metal plates in a three-shift operation, with one production cycle now taking only one to two hours compared to the four to eight hours needed before. The intralogistics system implemented for this solution also ensures that the machinery is utilized to a consistently high level. The impressive result of this pilot installation: production in the entire plant has been increased by 40% with a monthly machine output of 12,000 t.

General trend towards automation and digitalization

This project reflects the current trends in heavy industrial production: increasingly, solutions with a high degree of automation paired with digitalization of the production machinery are in demand. The goals are: the highest possible efficiency, optimizing of the production process and, understandably, reduction of risks and costs. The whole fabrication process has to be fast, smooth and transparent. In addition, the system also needs to be interconnected with the central warehouse, the order management system and onsite ERP system.

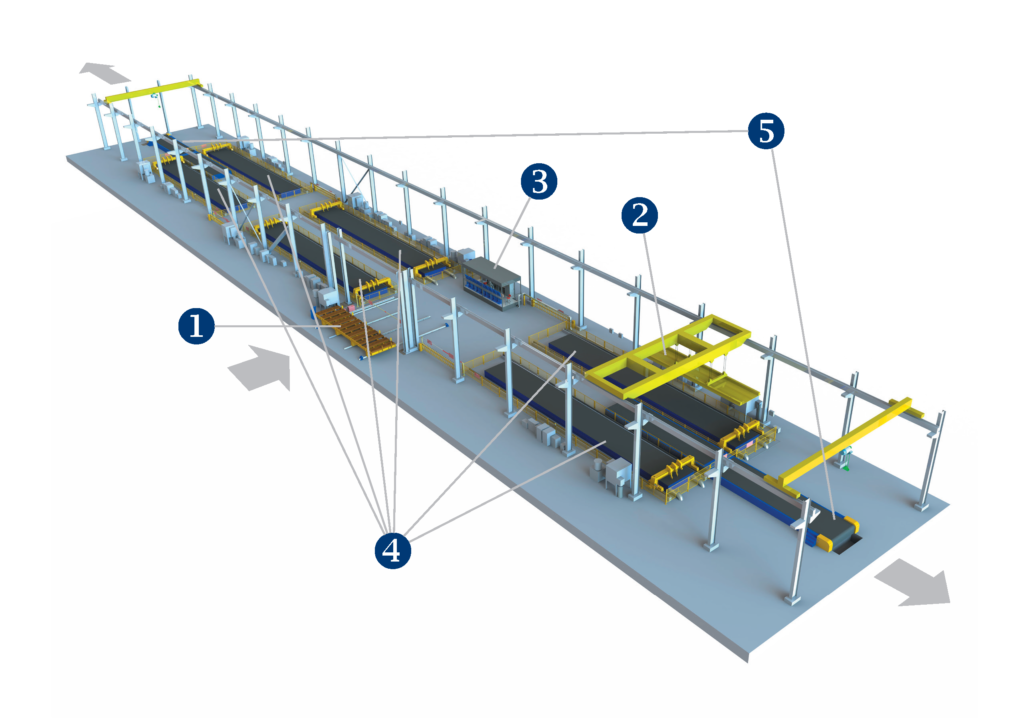

The automatic line installed at ZMJ consists of eight MicroStep CombiCut gantries with cutting areas of 28 x 3 m, each equipped with two high-definition plasma sources and an inkjet marker. In addition, there is an automated overhead crane (9 t x 16.5 m), an input wagon with a load capacity of 15 t and two output conveyors for collecting the cut parts and removal of waste material. The entire line is fully automated via MicroStep’s CyberFab Manager suite, with integrated software modules from Demag for crane management and material handling. The crane is moving on a 120 m long track in the height of almost 13 m. The production cycle runs as follows: the crane transports one of the plates (up to 12 m long and 40 mm thick) by means of strong magnet spreaders onto a free machine or into one of two buffer zones assigned to each of the eight CombiCut machines. After cutting, the crane moves the cut plates onto an output conveyor belt. Here, the plates leave the automated area and proceed to manual sorting.

An area measuring 120 x 18 m was fenced off within the production facility for the storage and processing of plates.

Here, the customer not only benefits from a better organized flow of material, but also from improved safety at the workplace: a dedicated access concept prevents any personnel from entering the individual processing areas when they are automatically approached by the crane.

When routine maintenance work is performed on one of the cutting systems, the automatic crane by-passes it as a danger zone in order to protect the personnel.

Management of the entire production process by CyberFab Manager

The entire manufacturing process is controlled by CyberFab Manager including control of the crane and conveyors. Through CyberFab Manager, every production step is coordinated and run automatically. Therefore, no active intervention from the operating personnel is required. The cut parts are automatically nested by MicroStep’s CAM software Asper® (nesting = material-saving distribution of parts on the plate by nesting algorithms in order to utilize the material to the maximum through minimizing waste), and after nesting, the corresponding cutting plan is generated for a particular plate from the stock. Generated cutting plans are then distributed to the individual CNC plasma cutting machines through CyberFab’s Machine Manager app. The crane automatically supplies available cutting machines with plates, based on information received from the material loader and control systems of the particular machines. The position and orientation of the plates in the cutting area is measured automatically by a laser sensor. Also, the cutting process is carried out fully automatically. After cutting, the cut parts and residual waste are moved by the magnetic crane to either of the two output conveyors. In this case, machine operators are only supervising the process, replacing consumables and providing maintenance.

❷ Automatic crane

❸ Control room

❹ CNC cutting machines

❺ Output conveyors